Background

The industrial application of biohydrometallurgy principally comprises the contribution of microbial activity to low-grade ore heap leaching and the use of stirred tank bioreactors for the liberation of gold from pyrite and arsenopyrite. Large scale heap bioleaching promotes recovery of target metals from copper ores (copper) and from polymetallic sulfides (currently nickel and zinc, and potentially copper, cobalt and uranium). Bioreactors for treatment of gold concentrates have been used in industry for over thirty years, with some reactors of over 1000 m3 currently in operation.

Particular acidophilic microorganisms use ferrous iron and/or sulfur as growth substrates, oxidizing them to produce ferric iron and sulfuric acid. These chemicals further attack mineral sulfides, mobilising the target metals and, in the case of refractory gold concentrates, result in the destruction of the sulfide matrix, releasing the gold for conventional downstream recovery.

Biohydrometallurgical Services Overview

Microbial cultures

GSL can utilise indigenous microorganisms from clients’ operation sites, if required, or can utilize an in-house collection of bioleaching cultures. This collection comprises a range of well-tested cultures, the most useful of which are stable microbial communities comprising several different species of microbe.

As well as having the ability to target different minerals, the varied stock of microbial cultures enables testwork over a wide temperature range. The operating temperature of ore heaps can range from relatively low temperatures to around 80 °C, depending on the ambient temperature and the extent of exothermic mineral sulfide oxidation in the heaps, and microbes need to be able to work effectively under these conditions. The use of thermophilic organisms in stirred tank reactors reduces cooling costs and utilizes the heat generated by exothermic mineral oxidations to provide faster and more efficient mineral dissolution.

- Microbial Cultures B

- Microbial Cultures A

- Microbial Cultures C

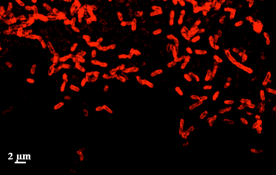

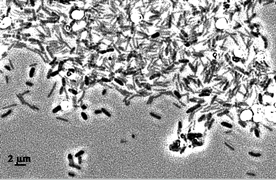

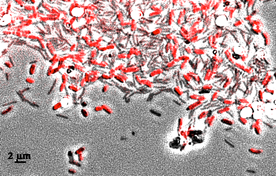

A moderately thermophilic community used in bioreactors at 45-55 degree C; (left) phase contrast microscopy of the culture showing Acidithiobacillus caldus, Acidithiomicrobium sp. and Sulfobacillus thermosulfidooxidans, (middle) the same view highlighting A. caldus stained with a species-specific fluorescent antibody, (right) overlay of previous two views.

- Microbial Cultures

High temperature archaea from a bioreactor (70 °C) with fluorescent stains indicating healthy (green) and dead (red) cells.

Low grade ore bioleaching

Cultures at GSL have been used in ore column testing of copper ores and black shale polymetallic sulfides, with some studies involving over one year of continuous operation. Small scale ore leaching columns (1kg ore) with controlled temperature, aeration and solution flow are available and there is the capacity for scale-up.

- Low Grade Ore Bioleaching 1

- Copper Ore leaching A

- Bioleaching A

Small scale ore percolation columns available for various process parameter investigations. Copper ore leaching in percolation columns at different temperatures at the start (left) and during (right) bioleaching with moderately thermophilic bacteria and thermophilic archaea.

Concentrate leaching / stirred tank reactors

GSL have the ability to assess the amenability of a sample to biological leaching. Typically, this involves batch tests, usually of up to two weeks duration (depending on concentrate type and temperature) in small scale reactors (up to two litres) with process control. Cultures at GS have been used for such diagnostic tests with various copper concentrates (particularly chalcopyrite), refractory auriferous pyrites and arsenopyrites, cobaltiferous pyrites and concentrates of nickel, copper/nickel and zinc.

A more robust assessment of biological leaching amenability can be done in continuous reactors. This test approach allows appraisal of long-term performance, or alternatively, it provides a means of creating a larger pregnant leach solution sample for further testing. Cultures at GS have been used in continuous testing (up to 300 days) of copper and of nickel concentrates, at temperatures from 45 to 78 °C.

Research and development

In addition to relatively standard ore and concentrate leaching amenability tests, there is in-house experience of investigation of further angles for potential biohydrometallurgy developments; these include the use of salt-tolerant bacteria and assessment of the potential of anaerobic bioleaching processes. We can also investigate the optimization of cyanide consumption in relation to the nature of gold-enriched bioleach residues and is especially well placed to investigate the optimization of ore fragment or particle size in ore heap leach and stirred tank reactor processes.

Contact Us

For more information on how biohydrometallurgy may be applicable for your project, or simply to find out more about biohydrometallurgy, please do not hesitate to contact us.